Knowledge 101

Welcome to Knowledge 101: EV Charging and Solar Solutions, your comprehensive guide to the essentials of electric vehicle charging and solar energy utilization. In this section, we provide a foundational understanding of key concepts, technologies, and best practices in the field.

- Core Components: The migration to an 800V platform requires the redesign and development of several high-voltage components such as air-conditioning compressors, PTC heaters, high-voltage distribution units (PDU), and DC-DC converters. These components must be engineered to withstand higher voltages while maintaining or improving efficiency and safety standards.

- Power Semiconductor Devices: The shift from traditional Insulated Gate Bipolar Transistor (IGBT) technology to Silicon Carbide (SiC) modules marks a significant evolution in power semiconductors. SiC devices offer superior performance, including higher efficiency, better thermal conductivity, and greater power density, which are crucial for optimizing the size and weight of the power electronics. Although initially more expensive, the cost of SiC technology is decreasing due to advancements in manufacturing techniques and wider adoption in the industry.

- Supporting Infrastructure: The effective implementation of 800V technology requires not only advancements in vehicle design but also in charging infrastructure. This includes the development of charging stations capable of delivering 800V power and enhancements to the electrical grid to support higher power demands. The infrastructure must be robust enough to support widespread use without compromising safety or convenience.

Looking Ahead

As 800V technology continues to evolve and become more integrated into mainstream automotive applications, it promises to reshape the landscape of electric vehicles by providing faster charging times, longer ranges, and enhanced overall performance. The ongoing innovations in battery technology, power electronics, and system integration play pivotal roles in driving forward this high-voltage revolution, making electric vehicles more appealing and practical for consumers worldwide.

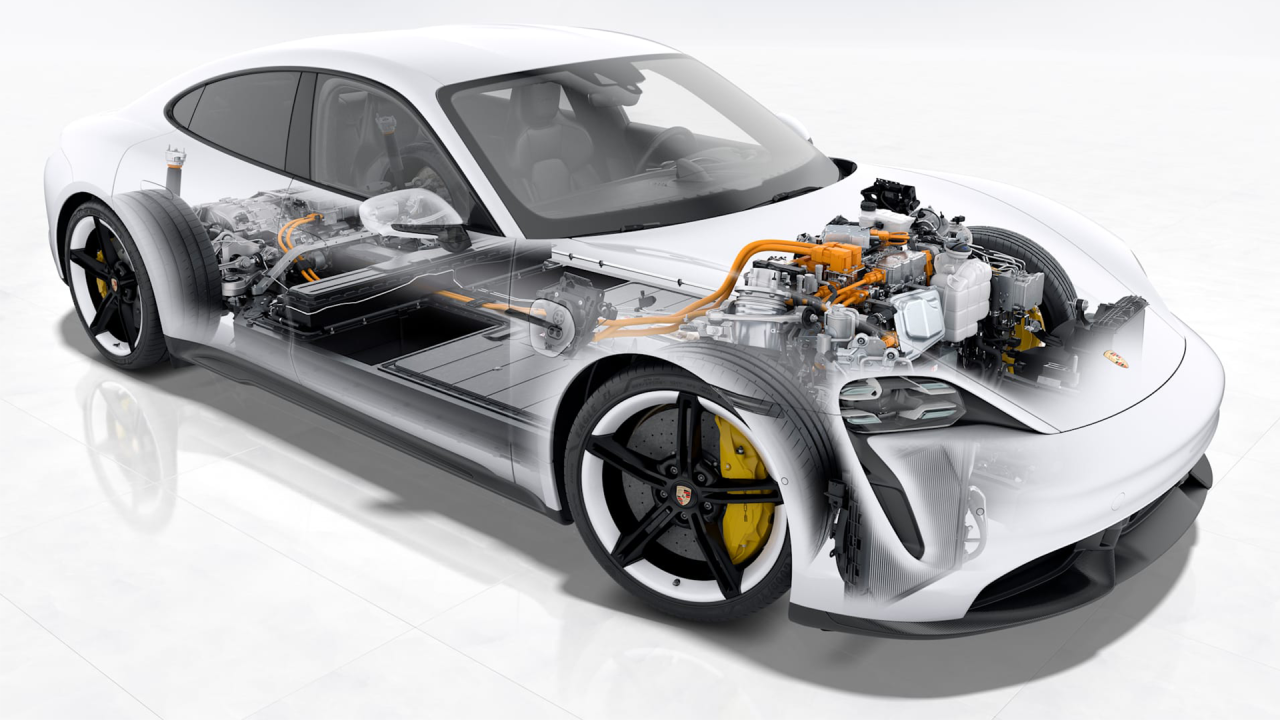

In 2019, Porsche set a new benchmark in the automotive industry with the introduction of the Taycan, the first vehicle equipped with an 800V high-voltage platform. This groundbreaking technology not only supports an 800V DC fast charging system but also accommodates 270KW of high-power fast charging, significantly reducing charging times and enhancing driving range. The adoption of 800V technology by other major automakers like Volkswagen, Mercedes-Benz, and Audi underscores its importance and the transformative impact it is poised to have on the electric vehicle market.

Comprehensive System Upgrades for 800V Implementation

The integration of 800V technology necessitates substantial upgrades across multiple vehicle systems:

- Battery System: At the heart of the electric vehicle, the battery system consists of several components including modules, casings, control units, and specialized cooling systems tailored to manage the increased power and heat generated by 800V operations. Innovations such as JiKrypton’s gold brick battery demonstrate the capabilities of 800V technology with features like 500kW charging power and a 4.5C charge rate, which can extend the driving range by over 500km in just 15 minutes of charging. This rapid advancement is mirrored by Maga CATL’s 5C Kirin battery, which boasts a 500km range replenishment in just 12 minutes.

- Electric Drive System: This system encompasses the drive motor, motor controller, and motor reducer. Modern electric drive systems are characterized by high integration, focusing on maximizing power while minimizing consumption and physical footprint. For instance, the development of oil-cooled flat wire motors adapted for the 800V platform highlights efforts to achieve higher power density and efficiency.

- High-Voltage Wiring Harness System: The shift to 800V allows for a reduction in the electrical current, which facilitates the use of thinner wiring harnesses, thereby reducing weight and heat generation within the vehicle. However, the transition from the established 400V systems presents challenges, primarily due to the incompatibility of existing wire harnesses and connectors with higher voltages. Furthermore, for charging powers exceeding 200kW, the implementation of liquid-cooled cables becomes necessary, although their bulkiness and the lack of established protocols for their integration pose significant challenges.

When comparing the two advanced solar technologies, TOPCon and HJT, each brings distinct advantages to the photovoltaic market, driven by their unique approaches to enhancing solar cell efficiency.

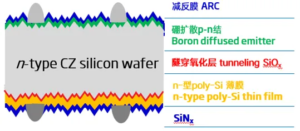

TOPCon (Tunnel Oxide Passivated Contact) technology, a direct successor to the P-type PERC method, has made significant strides by utilizing N-type silicon wafers. This method incorporates a passivation contact structure consisting of a silicon oxide layer and a doped polysilicon layer on the cell’s backside. This structure leverages tunneling principles to enhance carrier transport while effectively reducing recombination losses, thus boosting cell efficiency. The current practical efficiency of TOPCon cells has achieved about 24.5%, nearing its theoretical limit of 28.7%. The production process of TOPCon closely aligns with that of PERC, allowing manufacturers to upgrade existing PERC lines to produce TOPCon cells, resulting in lower transition costs and faster scale-up capabilities.

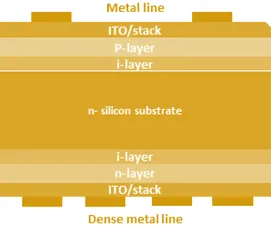

On the other hand, HJT (Heterojunction with Intrinsic Thin film) technology represents a significant departure from conventional doping methods by creating a heterojunction between amorphous silicon and crystalline silicon. This structure combines the advantages of crystalline silicon cells and thin-film technology, offering excellent passivation and a symmetrical double-sided design that leads to higher conversion efficiencies. The theoretical efficiency limit of HJT is around 27.5%. However, despite its higher efficiency and low light-induced degradation, the cost of HJT technology is generally higher than TOPCon due to the need for specialized low-temperature deposition processes and expensive materials like transparent conductive oxide (TCO).

In terms of cost-effectiveness, TOPCon appears more favorable in the current market. The investment for setting up a new TOPCon production line is approximately half that required for an HJT line, reflecting the lower material and process costs associated with TOPCon. Moreover, TOPCon utilizes high-temperature silver paste, which, despite being more costly than the low-temperature paste used in HJT, contributes to a more straightforward production process.

Ultimately, the choice between TOPCon and HJT technologies hinges on specific manufacturer priorities—whether the focus is on minimizing initial investment and leveraging existing infrastructure (favoring TOPCon) or achieving the highest possible efficiency and longevity at a higher cost (favoring HJT). Both technologies offer paths to significantly enhance the performance and economic viability of solar power systems, addressing different needs within the photovoltaic industry.

Energy storage systems (ESS) are important components of today’s electricity production landscape. One major reason is that these ESS help smooth out fluctuations in electricity use; this allows better integration of renewable energy sources to like solar and wind. Aside from that, ESS also play a role in managing peak demand periods and keeping the grid stable. They are also an important element in developing smarter power grid by optimizing the use of power equipment and even reducing energy costs.

What are Power Conversion Systems?

A Power Conversion System (PCS) is a bidirectional energy storage converter which acts as a bridge between the power grid and the storage units (like batteries). These converters are essential for systems that needs dynamic energy storage – which means systems that need to store and use energy flexibly. This includes systems connected to the main grid, those operating independently (off-grid), and even hybrid systems that can switch between both.

During low-demand periods, the PCS takes extra electricity from the grid and converts it to a form the battery can store (DC). When demand is high, the PCS converts the stored DC power back to AC and sends it back to the grid or uses it to power a local system (microgrid). This functionality of the PCS makes them valuable for both grid-connected and off-grid uses, and in integrating renewable energy sources to the grid.

Advantages of Power Conversion Systems

PCS converters work like traffic controllers for electricity. They use a special four-quadrant operation to efficiently convert between AC and DC power. This operation involves constantly adjusting the amount of power based on the microgrid monitoring signals, allowing the PCS to charge or discharge the battery while also ensuring stable power output. The PCS uses advanced controls and SPWM (Sinusoidal Pulse Width Modulation) to precisely adjust voltage, frequency, and power output. This helps the system respond quickly to changes in demand, regulate frequency, and maintain consistent power quality, all of which contribute to a more stable and reliable grid.

Operational Modes of Power Conversion Systems

There are three ways to operation the PCS. These are:

- Grid-Connected Mode: This mode allows for two-way flow of electricity between the battery and the grid. It includes features like automatic synchronization with the grid’s voltage and frequency, and protection against islanding (where a section of the grid becomes disconnected). The PCS manages battery charging and discharging based on grid needs or local controls, helping to manage energy use during peak demand periods.

- Off-Grid Mode: In this mode, also known as isolated operation, the PCS disconnects from the main grid and supplies AC power to local users from the battery, based on pre-set standards.

- Hybrid Mode: This flexible mode allows the system to switch between grid-connected and off-grid operation, depending on the status of the microgrid connection to the public grid. Normally, it operates while connected to the grid, but can easily switch to off-grid mode if the connection is lost. This ensures ensuring uninterrupted power and maintaining grid stability and power quality.

PCS converters truly have a critical role in managing and optimizing electricity distribution. Do you have additional questions about PCS or is there anything else you want to know about energy storage systems? Let me know in the comments below!