latest blog & article

- April 9, 2024

➡ Electric vehicles (EVs) are awesome, but charging them can take a while, especially at home with a regular charger. That’s where the mini DC charger comes in! Designed for fast and efficient charging, the mini DC charger can easily be mounted on your wall.

👉 When it comes to EV charging, we have two types of chargers: AC and DC chargers. AC chargers are regular chargers that are slower and typically used at home. It has a lower output power, ranging from 7kW for single-phase up to 11kW/22kW for three-phase. DC chargers or fast chargers are commonly found at public charging stations. They have higher power outputs which usually exceed 60kW.

⚡ The mini DC charger is right in between these two chargers in terms of charging speed. It charges faster than AC chargers, but not as fast as DC chargers. It typically operates within 20-40kW range.

💡 So, why would you want a mini DC charger?

⏩ One simple reason: faster charging at home! As EV battery capacities increase (some even go up to 100kWh!), it takes longer to charge them with a regular 7kW household AC charger. A mini DC charger can charge your car much faster at home.

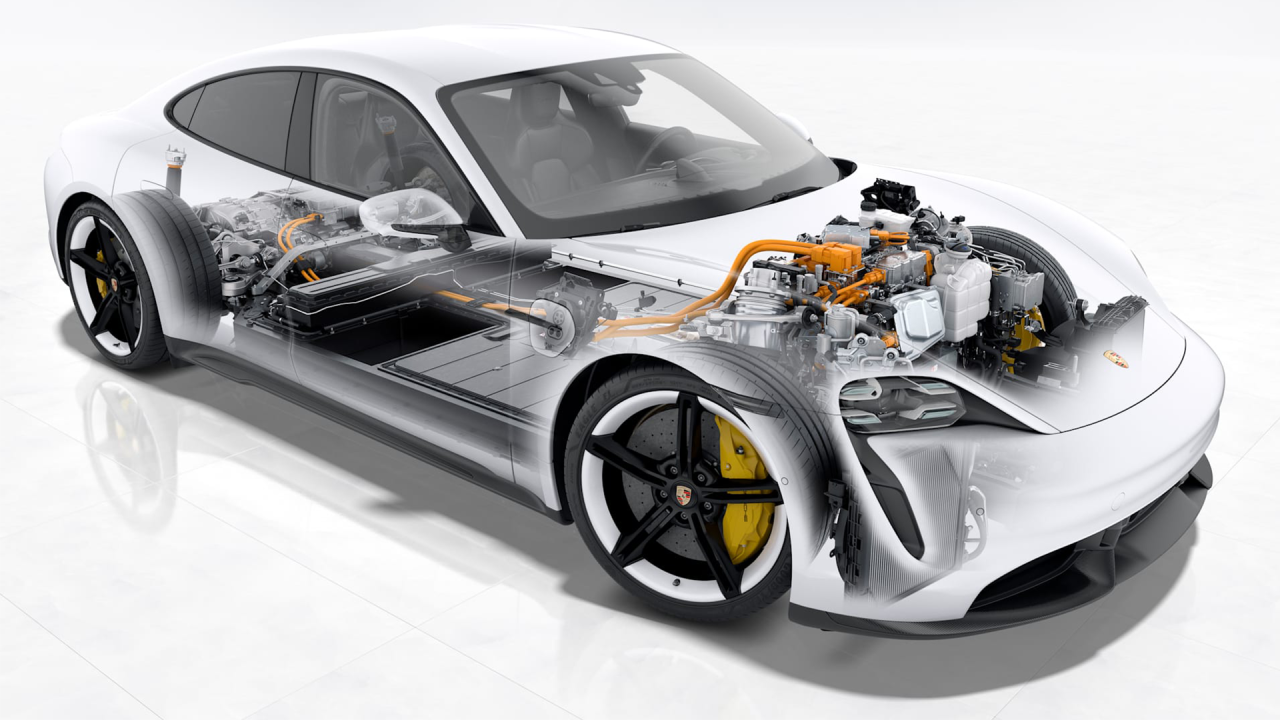

⏩ AC chargers usually need an onboard converter (OBC) to convert AC power to DC power. On the other hand, mini DC chargers are able to increase charging power without the need for OBC by incorporating the converter within the charger itself. While mini DC chargers may be smaller in size compared to high-power alternatives, they still offer faster charging rates.

❓ What’s next for mini DC chargers?

⏩ Mini DC chargers are also a good fit for some public places, like shopping malls. They’re not super-fast, but that’s okay because most people usually spend more than one hour in shopping malls. This means that installing high-power DC fast chargers may not be necessary as mallgoers won’t need a full charge within that timeframe. Using mini DC chargers in shopping malls may extend the charging times slightly but it still ensures that EVs are fully charged by the time the users are finished shopping. As a result, this frees up space and keeps the electricity grid happy.

✖ In the future, mini DC chargers could even change how EVs are built! With both AC and DC charging options currently in play, vehicles are equipped with OBCs for AC charging. However, transitioning to mini DC charging allows the removal of the AC charging interface and OBC, simplifying the vehicle design of EVs. It also makes EVs more reliable given the higher failure rate of OBCs. Lastly, removing OBCs also allows for cost savings in terms of materials and after-sales service.

😀 We’re Charge Ninja, and we’re excited about mini DC chargers!

We’re committed to delivering reliable, cost-effective charging solutions to customers worldwide. If you’re interested in exploring these solutions, don’t hesitate to contact us for further consultation and assistance.

- March 10, 2024

The solar industry has danced between monocrystalline and polycrystalline, each with its own pros and cons. Enter technological innovations, paving the way for more efficient, cost-effective solar modules. But what about the outdoor performance after a year and a half? Let’s break it down.

The Evolution of Solar Tech:

From diamond wire cutting to double-sided wonders, solar tech has witnessed remarkable innovations. But as we push the boundaries of component size, the focus now shifts to enhancing battery efficiency for further cost reduction.

Efficiency Breakdown:

P-type PERC modules have been the stalwarts, reaching around 23% efficiency, but progress has its limits. The real star, however, is N-type TOPCon, boasting a sky-high technical efficiency of 28.7%, with characteristics like low attenuation and high weak light response. It’s the go-to for many industries.

Comparative Power Play:

Enter the big players – TOPCon, HJT, and IBC. SPIC’s 18-month study reveals the following:

TOPCon Triumph: Among the trio, TOPCon steals the spotlight with the highest power generation capacity. Its bifacial ratio and attenuation rate outshine HJT and IBC components.

N-Type Dominance: N-TOPCon, N-HJT, and N-IBC show increasing power generation gains over time and varying temperatures. A note: this conclusion doesn’t extend to P-type IBC batteries in this study.

HJT Hurdles: Heterojunction components face challenges, evident in oxidized and blackened solder ribbons. Despite a higher operating temperature, the attenuation rate remains consistent at 9.37%. A sign that heterojunction manufacturing still has room to grow.

A Note of Caution:

While this data offers insights, it’s a snapshot. Different batches may yield different results, and tech is always on the move. The solar horizon holds endless possibilities. ☀️🔍 #SolarInnovation #RenewableEnergy #TechStudy

- March 9, 2024

Ever wondered about the wizardry behind your EV charger? Let’s dive into the world of two standard chargers – the tortoise (AC charger) and the hare (DC charger), each with its own flair.

1. AC Chargers (The Patient Ones) 🐢:

- Slow and steady wins the race. AC chargers tap into the power grid, letting the on-board charger (OBC) work its magic. It converts AC power to DC, ensuring a safe battery recharge.

2. DC Chargers (The Speed Demons) 🏎️:

- No time for conversions! DC chargers cut to the chase, converting AC power to DC directly, performing the fast-charging ballet without an on-board charger. Quick, efficient, and no time wasted.

The Anatomy of EV Chargers:

From shells to cables, each part plays a crucial role:

- Shell:Protector, supporter, and weather warrior. Good insulation and weather resistance are the superhero qualities of the shell material.

- Charging Plug:The handshake between charger and EV battery, ensuring a secure, high-voltage connection with locking and protection mechanisms.

- Control Panel:The command center with screens, buttons, and touch wizardry for charging status, cost intel, and user-friendly interactions.

- Electrical Module:Inverter or rectifier, these modules work their magic, converting AC to DC, ensuring the right voltage, and playing a vital role in the charging symphony.

- Power Controller, Metering Module, Communication Module, Safety Features, oh my!Each a superhero in its right, ensuring intelligent charging, precise measurements, seamless communication, and top-notch safety throughout the process.

800V Technology: The Game-Changer!

Undeniably, the rise of 800V charging brings a surge of upgrades:

- Electrical Performance Boost:Higher voltages demand better insulation and robust components. Think of it as the EV charger hitting the gym for a power boost, supporting fast charging up to 350kW!

- Safety and Intelligence:Things get hotter during high-power charging, but fear not – liquid cooling technology steps in. Real-time communication with your EV’s brain ensures a safe charging experience, preventing overcharging and thermal runaway.

- Power Grid Harmony:No chaos here. Intelligent dispatching and energy storage devices make sure your high-voltage charging doesn’t throw the power grid into a frenzy. It’s all about balance and stability.

Liquid-Cooling Charging: The Hottest Topic! 🔥

In the realm of innovations, liquid-cooling charging steals the spotlight. Dive deeper into its wonders in our previous articles. liquid-cooling charging Stay charged, stay informed! ⚡🌐 #EVCharging #TechRevolution #800VTechnology

- March 8, 2024

Ever wondered about the wizardry behind your EV charger? Let’s dive into the world of two standard chargers – the tortoise (AC charger) and the hare (DC charger), each with its own flair.

1. AC Chargers (The Patient Ones) 🐢:

- Slow and steady wins the race. AC chargers tap into the power grid, letting the on-board charger (OBC) work its magic. It converts AC power to DC, ensuring a safe battery recharge.

2. DC Chargers (The Speed Demons) 🏎️:

- No time for conversions! DC chargers cut to the chase, converting AC power to DC directly, performing the fast-charging ballet without an on-board charger. Quick, efficient, and no time wasted.

The Anatomy of EV Chargers:

From shells to cables, each part plays a crucial role:

- Shell:Protector, supporter, and weather warrior. Good insulation and weather resistance are the superhero qualities of the shell material.

- Charging Plug:The handshake between charger and EV battery, ensuring a secure, high-voltage connection with locking and protection mechanisms.

- Control Panel:The command center with screens, buttons, and touch wizardry for charging status, cost intel, and user-friendly interactions.

- Electrical Module:Inverter or rectifier, these modules work their magic, converting AC to DC, ensuring the right voltage, and playing a vital role in the charging symphony.

- Power Controller, Metering Module, Communication Module, Safety Features, oh my!Each a superhero in its right, ensuring intelligent charging, precise measurements, seamless communication, and top-notch safety throughout the process.

800V Technology: The Game-Changer!

Undeniably, the rise of 800V charging brings a surge of upgrades:

- Electrical Performance Boost:Higher voltages demand better insulation and robust components. Think of it as the EV charger hitting the gym for a power boost, supporting fast charging up to 350kW!

- Safety and Intelligence:Things get hotter during high-power charging, but fear not – liquid cooling technology steps in. Real-time communication with your EV’s brain ensures a safe charging experience, preventing overcharging and thermal runaway.

- Power Grid Harmony:No chaos here. Intelligent dispatching and energy storage devices make sure your high-voltage charging doesn’t throw the power grid into a frenzy. It’s all about balance and stability.

Liquid-Cooling Charging: The Hottest Topic! 🔥

In the realm of innovations, liquid-cooling charging steals the spotlight. Dive deeper into its wonders in our previous articles. liquid-cooling charging Stay charged, stay informed! ⚡🌐 #EVCharging #TechRevolution #800VTechnology

- February 9, 2024

In my previous article, I discussed the applications of mobile emergency energy storage vehicles. Now, let’s dive deeper into the internal structure of these mobile battery vehicles. They consist of the following key components:

1. Lithium Iron Phosphate (LFP) Battery System

The LFP Battery System is the core of mobile battery vehicles. It is comprised of multiple battery packs, a high-voltage main control box, and a Power Conversion Systems (PCS) set.

The energy storage component used Lithium Iron Phosphate which has the following characteristics: high energy density, long cycle life, and large charging and discharging rates. Aside from that, it is also safe and eco-friendly. This battery pack is secured into a battery holder using screws and plywood at the front and back.

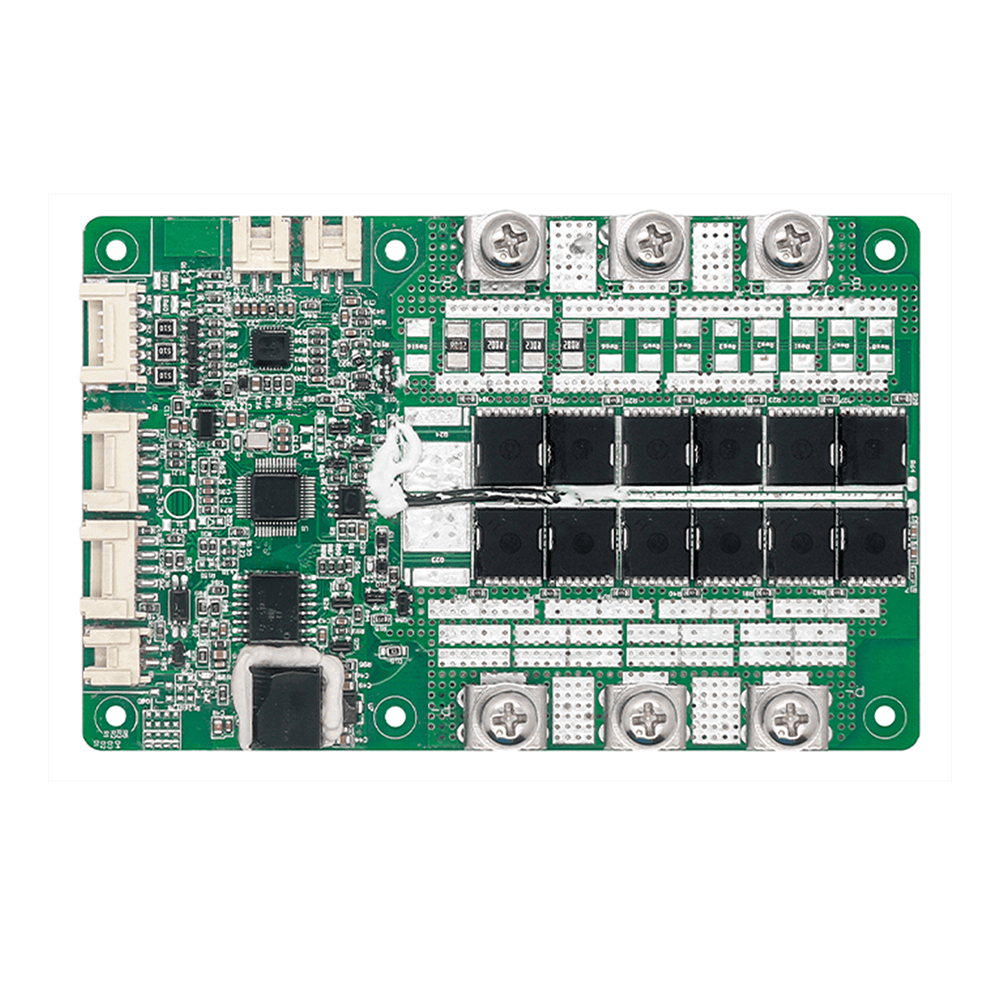

Another component of the battery system is the BMS or Battery Management System, which is used to monitor the health of energy storage batteries. It is used to intelligently manage and maintain each battery unit, preventing the battery from overcharging and over-discharging which helps extend the battery’s service life. You’ll usually find the BMS as a circuit board or a hardware box.

Finally, another essential component is the Power Conversion Systems (PCS) set. In addition to the bidirectional inverter function, the PCS set can also support the grid, ensuring the stable operation of the grid system. It provides resistance to short-term impact, a smooth power supply, energy storage, and peak shaving.

LFP Battery Systems have many applications including electric vehicles (EVs), peak shaving, frequency modulation, emergency backup power supply, and more.

2. Uninterruptible Power Supply (UPS)

An Uninterruptible Power Supply (UPS) is a system device that connects the battery (lead-acid maintenance-free batteries) to the host and converts DC power into commercial power through module circuits such as the host inverter. UPS power serves as a backup power supply during equipment startup.

3. Gyroscope

A gyroscope is a high-performance 3D motion attitude measurement system based on MEMS technology. It has motion sensors such as a three-axis gyroscope and a two-axis accelerometer. It integrates these high-performance sensors and uses a self-developed attitude dynamics core algorithm engine. Combined with a Kalman filter fusion algorithm, a gyroscope provides high-precision, highly dynamic, and real-time compensated three-axis attitude angles—offering flexible selection and configuration of various data types to meet different application scenarios.

4. Infrared Camera

An infrared temperature sensor is essential for the interior monitoring system. This sensor connects to the equipment host through RS485 communication, enabling real-time monitoring of the internal environment.

5. Heat Dissipation System

The primary equipment in the electrical room, the PCS system, utilizes direct exhaust cooling to maintain proper temperature. The battery compartment uses industrial air conditioning to control the temperature.

6. Fire Protection System

Safety is very important, so these vehicles come with special fire extinguishers that use heptafluoropropane (HFC-227ea) gas. Heptafluoropropane is a widely used product known for environmental protection, safety, and economic costs. Heptafluoropropane fire extinguishers are colorless, odorless, and don’t conduct electricity. They are also not very toxic and don’t create any extra pollution.

Its fire-extinguishing mechanism is similar to methylalkane series fire-extinguishing agents. During combustion, the fire-extinguishing agent decomposes thermally, generating fluorine-containing free radicals. These free radicals (H+, OH-, and O2-) react in the gas phase to suppress the chemical reaction during combustion, effectively extinguishing the fire.

7. EMS system

The core Energy Management System, or EMS, is another critical component. The EMS is directly responsible for the control strategy of the energy storage system. This control strategy significantly impacts the battery’s decay rate and cycle life, ultimately affecting the economic viability of the energy storage system. The EMS also monitors for system abnormalities during operation to provide timely and rapid troubleshooting, ensuring equipment protection and overall safety.

These are the essential parts that make up a mobile emergency battery vehicle. Optimal performance and safety rely on the scientific integration of these various systems. If you’re interested in such a solution, send us a message at Charge Ninja.

- February 9, 2024

Ever wondered if your electric vehicle could charge in just five minutes and zoom off for 300 kilometers? Enter liquid-cooling charging—the game-changer in tackling the notorious range anxiety.

What’s the buzz about liquid-cooling charging?

It’s like giving your EV a spa day during charging! 🚗💆♂️ A special liquid circulation channel works its magic between the cable and the charging plug. Coolant flows through, dissipating the charging process’s heat, all thanks to a power pump. The result? A cool charging experience with an impressive IP65 grade.

Advantages that make waves:

- Speed Demons Rejoice! 🚀 Liquid-cooling chargers break free from the limitations of traditional ones. The secret? Cables and water pipes inside make way for more current, charging faster without breaking a sweat.

- Lighter than Air! 🌬️ Say goodbye to heavyweight chargers! Liquid-cooled charging plugs shed 30% to 40% of the weight compared to their traditional counterparts, thanks to sleeker wire diameters.

- Cool, Calm, and Collected! ❄️ Heat dissipation becomes an art form. With a fully liquid-cooled design, chargers stay chill, achieving IP65 protection. It’s like a cool customer in the face of charging challenges.

- Silence is Golden! 🤫 No more loud fans disrupting the peace. Liquid-cooled chargers keep it hush-hush with water pumps handling heat dissipation. Less noise, more serenity, especially during those quiet nighttime charges.

- Life’s a Marathon, Not a Sprint! 🏁 Liquid-cooled chargers outlast the competition, boasting a service life of at least ten years. Maintenance? A breeze. No frequent openings or dust removal—just a simple flush when needed.

Ready to revolutionize your EV charging experience? Liquid-cooling charging is the future, where speed meets efficiency, and your electric ride becomes a stress-free journey!

- February 8, 2024

Imagine a world where you don’t need a wall socket to turn on the lights. Imagine having electricity that follows you around, ready to light up any situation, anywhere. This isn’t science fiction, this is a reality that we can enjoy today thanks to mobile battery vehicles!

What are Mobile Battery Vehicles?

Mobile Battery Vehicles are basically super-powered electric cars. They are packed with enough electricity to keep things running smoothly at events, construction sites, even during emergencies. Forget noisy, gas-guzzling generators – mobile battery vehicles are like silent superheroes, saving the day with clean, dependable power.

From Fuel to Battery: A Green Transition

Back in the days, when we think of mobile power, we meant noisy, fuel-powered generators. But nowadays, we have a cleaner and more sustainable option: battery power! These mobile batteries are not only better for the environment, they’re also smarter, quieter, and quicker to use with its plug and play capabilities. And if those advantages are not enough – they are even cheaper to use! Costs are usually 40% less than their gas-powered counterparts.

How do Mobile Batteries Work?

These batteries are not the same as your average car batteries. These units are made up of special lithium iron phosphate batteries – which stores tons of energy and keeps everything running smoothly.

They also have additional features like built-in inverters which convert stored energy into usable power and smart management systems that make sure everything runs safely and efficiently. Some of these mobile batteries can power entire buildings, with up to 500,000 watts of power and enough juice to keep things going for over a day!

Introducing Our Mobile Power Solution

We’ve taken the mobile power technology to the next level with our series of mobile lithium battery power supply vehicles. With storage capacities stretching from 80kWh to 500kWh and equipped with cutting-edge DC/DC EV chargers and bidirectional converters, these vehicles are not just backup power sources. That’s enough to power a small party or keep a whole festival lit up!

Aside from that, they also have special chargers that can rescue electric vehicles with a dead battery, and can even help manage power usage during peak hours with its peak load management feature. Plus, they work with all sorts of electric vehicles, so no one gets left in the dark. Thanks to their broad voltage DC output, they’re ready to meet the diverse demands of the evolving EV landscape.

Having powered projects across Europe, the Middle East, and Southeast Asia, our mobile power supply vehicles are paving the way for a brighter, greener, and more connected world.

So, are you ready to join the mobile battery revolution? Let’s drive towards a cleaner, brighter future, together!

- January 9, 2024

Big news from the EV world in Germany! The Federal Ministry for Economic Affairs and Climate Protection (BMWK) has officially closed the chapter on the electric vehicle subsidy program, effective December 16. As of Monday (December 18), no new applications for EV subsidies are being accepted.

Why the Change?

Budget constraints have driven this decision responding to a recent ruling by Germany’s Federal Constitutional Court. They nixed the use of 60 billion euros initially allocated for an epidemic response fund, creating a 17 billion euro gap in the 2024 federal budget. Consequently, subsidies for electric vehicles, solar energy, and more got the budget cut axe.

The Impact So Far:

Reports reveal Germany invested a whopping 10 billion euros in subsidies for approximately 2.1 million electric vehicles since 2016. While the subsidy program was set to run until 2024, it has been halted due to recent budget constraints. Despite this pause, Germany remains committed to getting 15 million electric vehicles on the road by 2030.

Charge Ninja’s Stance:

Here at Charge Ninja, we’re all about rolling with the punches. Changes in the subsidy landscape won’t hit the brakes on our commitment to providing you with cutting-edge charging solutions. We’re geared up for innovation and ready to adapt to whatever the road ahead brings.

🔗 Stay Charged with hashtag#ChargeNinja for Future Updates!