When comparing the two advanced solar technologies, TOPCon and HJT, each brings distinct advantages to the photovoltaic market, driven by their unique approaches to enhancing solar cell efficiency.

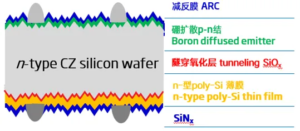

TOPCon (Tunnel Oxide Passivated Contact) technology, a direct successor to the P-type PERC method, has made significant strides by utilizing N-type silicon wafers. This method incorporates a passivation contact structure consisting of a silicon oxide layer and a doped polysilicon layer on the cell’s backside. This structure leverages tunneling principles to enhance carrier transport while effectively reducing recombination losses, thus boosting cell efficiency. The current practical efficiency of TOPCon cells has achieved about 24.5%, nearing its theoretical limit of 28.7%. The production process of TOPCon closely aligns with that of PERC, allowing manufacturers to upgrade existing PERC lines to produce TOPCon cells, resulting in lower transition costs and faster scale-up capabilities.

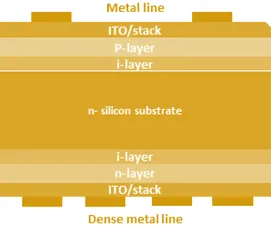

On the other hand, HJT (Heterojunction with Intrinsic Thin film) technology represents a significant departure from conventional doping methods by creating a heterojunction between amorphous silicon and crystalline silicon. This structure combines the advantages of crystalline silicon cells and thin-film technology, offering excellent passivation and a symmetrical double-sided design that leads to higher conversion efficiencies. The theoretical efficiency limit of HJT is around 27.5%. However, despite its higher efficiency and low light-induced degradation, the cost of HJT technology is generally higher than TOPCon due to the need for specialized low-temperature deposition processes and expensive materials like transparent conductive oxide (TCO).

In terms of cost-effectiveness, TOPCon appears more favorable in the current market. The investment for setting up a new TOPCon production line is approximately half that required for an HJT line, reflecting the lower material and process costs associated with TOPCon. Moreover, TOPCon utilizes high-temperature silver paste, which, despite being more costly than the low-temperature paste used in HJT, contributes to a more straightforward production process.

Ultimately, the choice between TOPCon and HJT technologies hinges on specific manufacturer priorities—whether the focus is on minimizing initial investment and leveraging existing infrastructure (favoring TOPCon) or achieving the highest possible efficiency and longevity at a higher cost (favoring HJT). Both technologies offer paths to significantly enhance the performance and economic viability of solar power systems, addressing different needs within the photovoltaic industry.